Quality selection of raw materials

Quality raw materials and parts guarantee the quality of the device

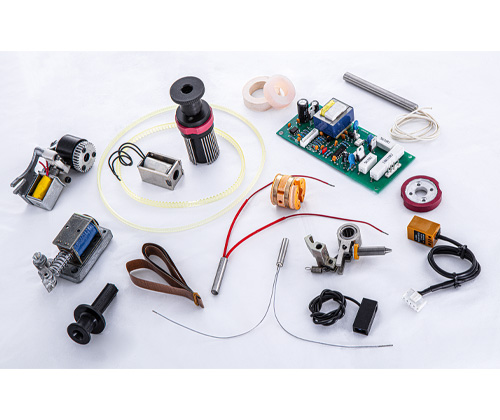

Quality control of parts

Every part that is used or used in the device is of great priority for us. Therefore, we always use quality parts with tested performance.

The performance and quality of all parts are confirmed by control engineers before installation.

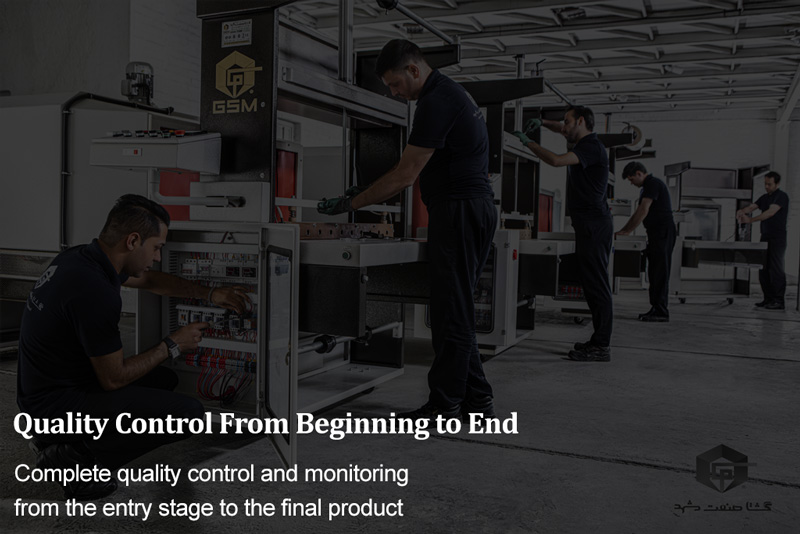

A set of quality control tasks

The company's quality control department has comprehensive work instructions to perform cycles and standard controls in three situations: before the production of primary parts - during and during construction and after construction, and at each stage, forms and checklists The relevant is completed.

Recruiting expert staff with relevant experience in the field of quality control is one of the other principles of our company.

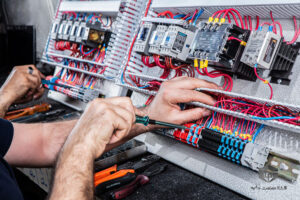

Accurate device control

Quality control inspectors check all the parts according to the checklist and standard forms after completing the manufacturing and assembling process of the device to ensure the correct functioning of the device.

All different components and parts such as engines, gearboxes, electronic parts, electrical panels or pneumatic parts, etc. are controlled and reviewed completely and part by part in operational tests and situations.

Detailed testing and no-load performance testing

Testing, operational testing and simulating the actual working condition of the device is one of the principles of the quality department of our company.

After the production and assembly of the device, the quality experts put the device in working mode without the product and with the product for the necessary time, so that no problem occurs during the installation and commissioning and the device is under load, or if corrections are needed. It must be done.

If the product is specific or the buyer sends a sample, our experts will test and test the device after production with the product sample to ensure its correct operation.

Packaging and final control

Maintenance and cleaning of the device after production, assembly and quality tests as well as suitable and reliable packaging help to maintain and maintain quality.

Our quality experts control all the parts of the device so that the traces of production and possible stains are removed and the device is transferred to the packaging department with a favorable appearance.

In the packaging section, the device is packed according to the type of device and its shipping location.

The devices are packed at the company's premises in two standard and reliable ways using wooden pallets and cardboard boxes to protect the device from possible damage during shipping.